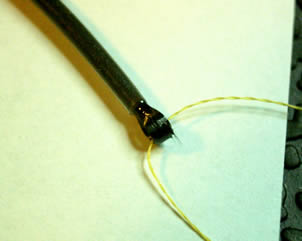

Left, wetted carbon tows pulled through fuel tube with Kevlar thread. Right, after curing in oven.

Left, close up of rod, some sanding shows a little too much surface epoxy.

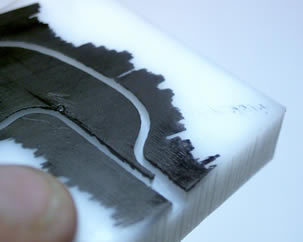

Making an ornithopter bumper with a delrin mould.

Above left, CNC cut mould. 1mm cutter, 2mm deep slot. Black marker to make cut visable for photo. Right, strong thread doubled over and placed in mould. Was wetted a little to keep it in place.

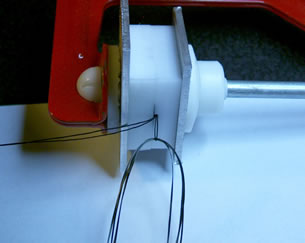

Above right, Another delrin plate was used for the top of the mould, then aliuminium stiffeners were added and the whole thing clamped. Doubled over tows are threaded through the pulling thread. The number of bunches determined by tial and error.

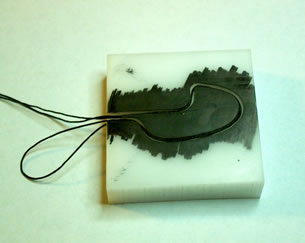

Above left, the tows were wetted out on a platic sheet, a piece of foam (and a glove) used to apply the laminating epoxy. Above right, after pulling the carbon through the excess was trimmed.

After baking for 15min at 50degrees C the mould was broken apart and the piece removed. No release agent was used but it would have made it easier. The part was then cooked for a further 10min at 100 degrees C to really set it good!. Above right, the finished part after finishing, the part was trimmed and sanded to give a taper to the tip.

Conclusion: Carbon is fun, The bumper needed more tows and a thinner pulling string. Release agent would have helped with the delrin mould but suprisingly was not absolutely required.