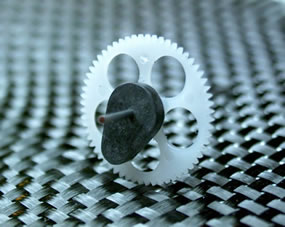

This part is for my 12" RC ornithopter. The idea is that the crank wire engages with it and it in turn engages directly with the small gear on the front of the spur gear used.

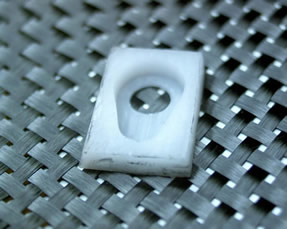

Here is the mould, CNC milled from Delrin

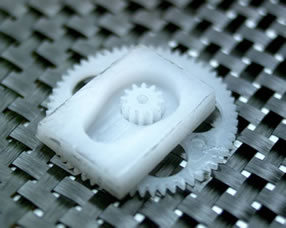

The Didel gears are also Delrin and this is inserted into the back to finish the mould and provide the form for the internal teeth.

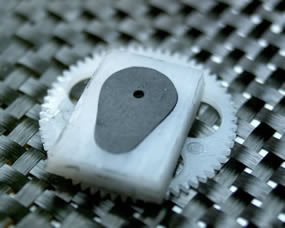

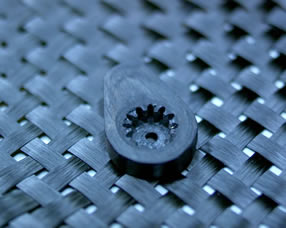

Here is the part after moulding. Moulding involved the careful placement of epoxy wetted tows into the cavity such that I had tows running around the perimeter. Once I had as much of these in place as I could manage and mixture of chopped carbon tow and epoxy was pressed into the cavity. It was generally piled up so there was hopefully much more carbon that could fit in. A Delrin block was then clamped on top with a heavy duty clamp and the whole thing baked. The clamping and some of the general pressing ensured that the excess epoxy was squeezed out

Here is the finished part in the mould this is after some gentle cleaning. The hole was not moulded in either but just drilled using the gear as a guide.

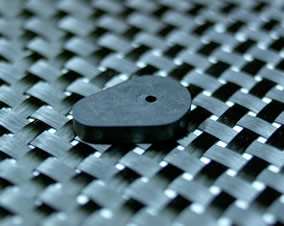

This is the finished part, it looks just as good in the flesh, you could even see the machining marks on the other side and also the evidence of the way the tows were laid up. This is the top where most of the carbon is the chopped tow mush so it looks a little like carbon tissue.

Here is the bottom of the part showing the teeth. Some were lost during extraction of the part but I am sure with a higher strength epoxy and some of the finer chopped tows around that area they would have come out perfectly. As they are they work more than well enough.

The finished part in place, a hole also needs to be drilled towards the outside to except the crank driver pin but that can come later.

Conclusion: I might do this again!